Continuous Casting Machine Process

3000000 INR/Unit

Product Details:

- Product Type Continuous Casting Machine Process

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Coated

- Usage & Applications Industrial

- Click to View more

X

Continuous Casting Machine Process Price And Quantity

- 1 Unit

- 3000000 INR/Unit

Continuous Casting Machine Process Product Specifications

- Continuous Casting Machine Process

- Semi Automatic

- Coated

- Electricity

- Industrial

Continuous Casting Machine Process Trade Information

- Kolkata

Product Description

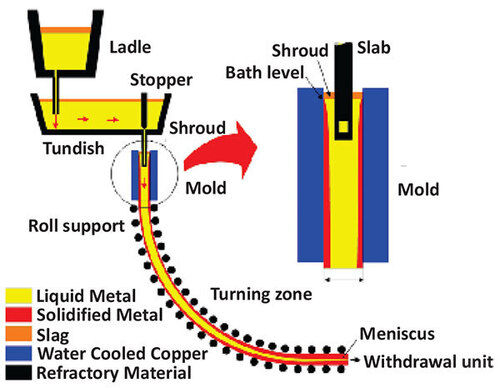

Continuous casting enables the production of advanced alloys with precisely controlled metallurgical properties. These materials, such as aluminum, titanium, and nickel-based alloys, are used in the construction of critical components like airframes, engine parts, and structural components.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semi finished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots.

The importance of casting in manufacturing is that it allows for the production of complex and intricate metal components cost-effectively. Casting reduces the number of individual parts required, as multiple pieces can be cast as a single unit.

Enter Buying Requirement Details